M-Form gives architects, engineers, contractors and their clients the freedom to design doubly curved surfaces and fabricate them in a fraction of the time, material, and energy than current manufacturing methods offer.

Exterior Cladding Example

Translucent Acrylic Panel and Solid GFRC Panels

The canopy example shown above illustrates M-Form’s extensive capabilities to create freeform design with variably shaped paneling. Each panel is unique and M-Form can be used to make all of them with minimal cost and time implications.

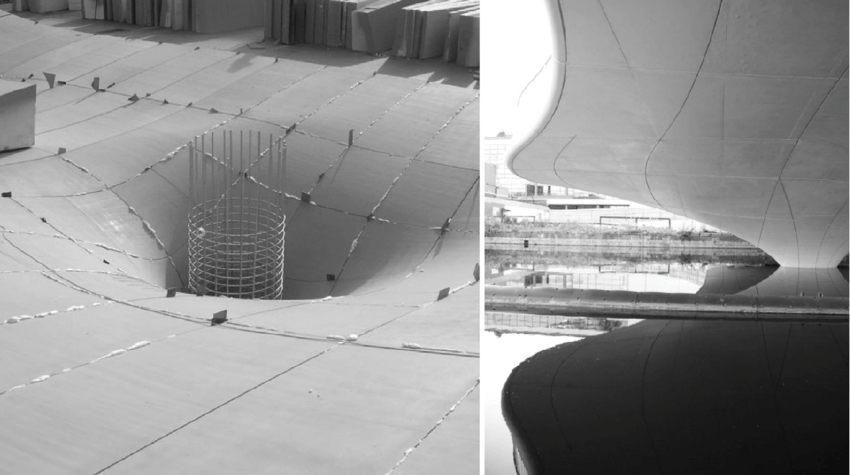

Cast-in-Place Formwork Example

M-Form is also a Cast-in-place (CIP) solution for many different project types including bridges, walls, pylons, and other specialty structures. By providing form liners for on-site CIP construction, M-Form expands the current capabilities of the industry and pushes the limits on design.